How To

Please refer to the buffing chart at the bottom of this tab for the steps necessary to restore plastic.

Keep in mind, if you are looking to achieve the best possible finish, you will need to do all stages of sanding and polishing. You cannot go right to the final step and expect a great finish. Plastics (especially white) that are yellowed from fuel cannot be fixed with this method. Crease marks from bending also cannot be sanded or polished out.

Sanding

-Sanding is the most important step in plastic polishing, take your time and follow each step carefully.

-Clean your part thoroughly prior to sanding.

-Position your part so it stays in place while sanding. For example, most gas tanks fit over a saw horse. This will make sanding much easier.

-If your part has deep scratches, start with 320 grit sandpaper. For parts with minor scratches, begin with 400 grit. You will work your way up to 2000 grit in the remaining steps.

-Start by sanding dry with the first grit of sandpaper you choose. Once the sandpaper starts to lose it’s effect, sand the part with soapy water to clean it.

-Sand in different directions and patterns to achieve the most uniform finish. Use light to medium pressure while sanding, heavy pressure can gouge the part.

-Keep the sander moving across the part, do not stay in one area for very long. Keep the sander flat on the part to prevent dips in surface.

-Use machine sanders at medium speed. If using a drill to sand, you must use the provided foam pad to prevent gouging of the part.

-Keep sandpaper clean during sanding process.

-After the first sanding grit, check for any leftover scratches or pits. If they are not removed in the first stage of sanding, they will be visible in the final finish.

-You can check for scratches using the provided guide coat. Sprinkle a small amount of powder onto the part and rub it around with soapy water and a towel. The powder will fill any remaining scratches and make them visible. Once any scratches are located, sand them out and wipe off guide coat.

-After the first grit of sanding has been done, use wet sanding only for the remaining grits.

-Spend adequate time with the second grit of sandpaper, it is very important to remove scratches from the first grit of sandpaper.

-The final sand on each grit should be used with little pressure, let the machine or sanding block just glide along the part on each pass.

-Tighter areas may have to be sanded by hand, it can be tough get into crevices with a machine sander.

-Once you have sanded up to 2000 grit, clean the entire part with isopropyl alcohol and now you are ready for polishing!

Polishing

Step 1

-It is a good idea to test the polishing steps on a scrap piece beforehand, so you know how much pressure can be safely applied.

-Secure the polishing wheel marked “1” to buffer with a flange on either side. The first step uses a polishing compound to help smooth scratches from sanding.

-Apply compound to the spinning wheel for 2-3 seconds to allow it to melt on the wheel. It’s normal for fibers to fly off the during the first 30 seconds of use.

-Start with light pressure and move to very light pressure towards the end of each step.

-The polishing wheels must be used with caution, since heavy pressure will result in burns.

-Polish in different directions and patterns to achieve the most uniform finish.

-Keep the wheel moving across the part, do not stay in one area for more than a few seconds.

-The sweet spot to buff on the wheel is between 4 and 5 o’clock. Look at your buffing machine from the left side, and picture where 4 and 5 o’clock is on the wheel, it will be near the bottom. That is where you will want the part to touch the wheel when buffing.

-In order to prevent burning the plastic or flinging the part out of your hands, be careful around edges. The wheel should be spinning away from an edge and not towards it.

-Re apply compound when the polishing effect lessens. Every 2 to 3 minutes is a good interval.

-As you're polishing, any areas you missed while sanding will start to appear. Some areas may polish out during this step, while the larger imperfections will require additional sanding.

-Once you see a smooth scratch free finish, you are ready for the second step of polishing.

-After the first step of polishing, you MUST clean the part with isopropyl alcohol or contact cleaner to remove the polishing compound.

-Do not mix the wheels up, the wheel stamped with 1 is used for the first step, 2 is used for the final step.

Step 2

-Secure the polishing wheel marked “2” to buffer with a flange on either side. Do not use any polishing compound on this wheel. Use the same techniques described in step 1, without the compound.

-If you have a hazy finish, keep polishing with very light pressure and move slowly across the part until you achieve a clear glossy finish. Do not apply heavy pressure.

-If you notice any areas that have scuffs, you can go back to step 1 of polishing to correct these.

-Always wear a dust mask or respirator and eye protection while buffing!

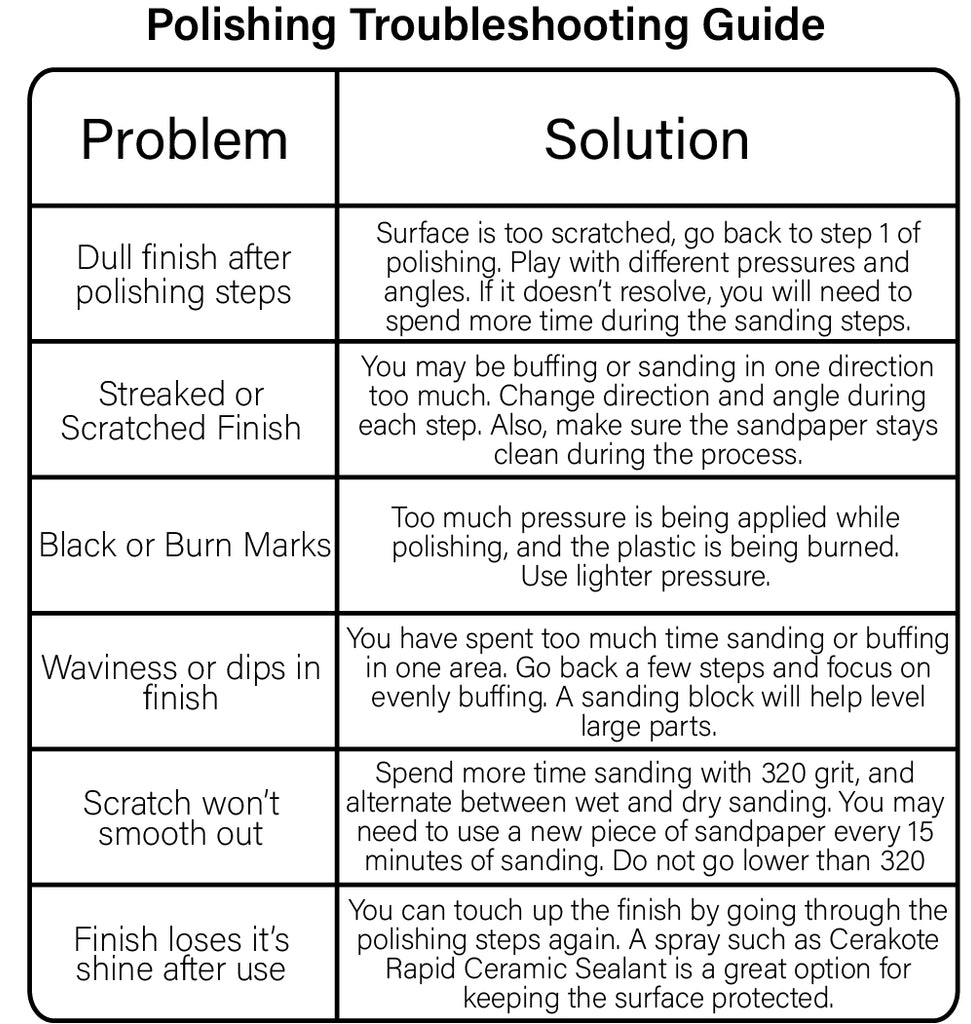

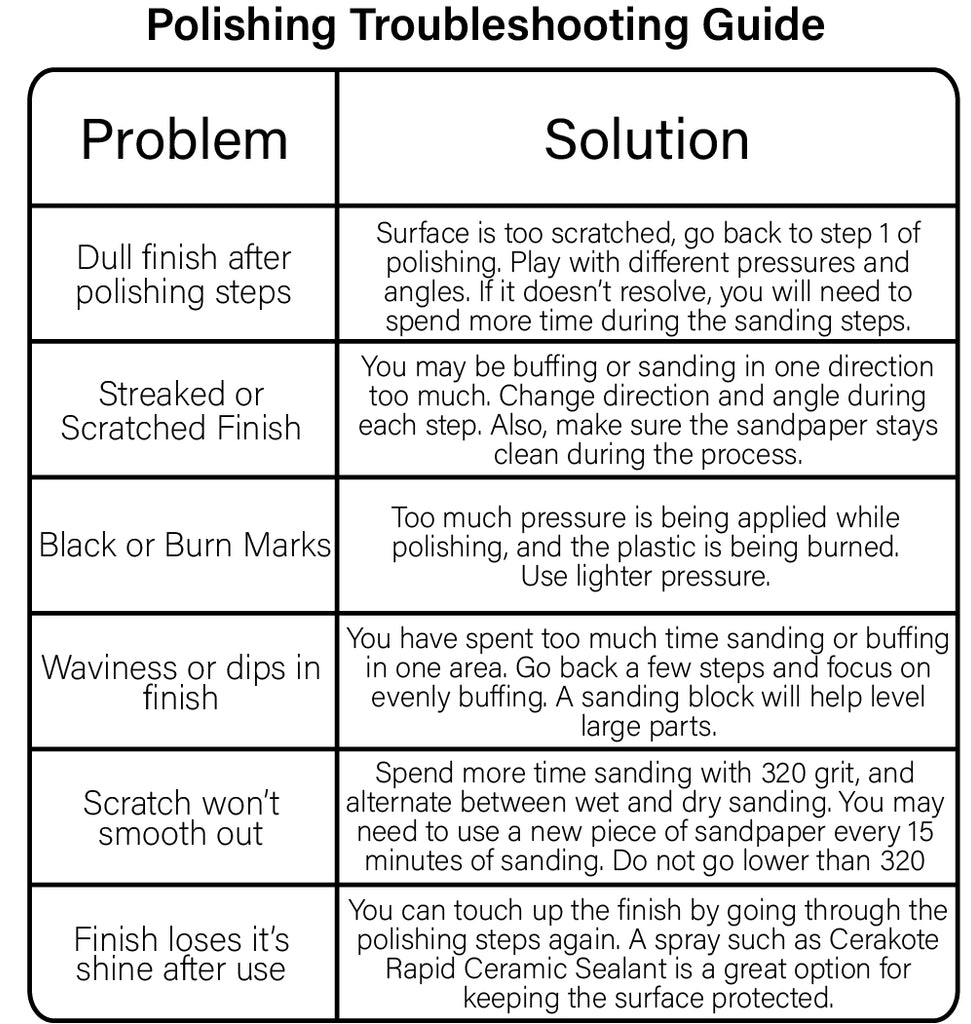

-If you have problems while polishing, refer to the troubleshooting guide at the bottom of this tab.

After Polishing

It is not recommended to use a clear coat over plastic, since the durability is not great and it poses a larger problem once it needs to be stripped off. A good temporary protectant is the Cerakote Ceramic Sealant.

Sander Recommendations

Drill (you'll want one that goes up to 3000 RPM for best results)

5" Electric Sander

6" Pneumatic Sander

Buffer Recommendations

1/2 HP Buffer

3/4 HP Buffer